TRADE AND PROCESSING

OF ALUMINUM

TRADE AND

PROCESSING

OF ALUMINUM

ECO-FRIENDLY SOLUTIONS

Thanks to collaboration with rolling mills and foundries located in Europe and the rest of the world, TradeUp provides a vast selection of products that meet the growing needs of the market.

We are committed to safeguarding the environment and pay particular attention to the choice of raw materials, seeking eco-sustainable solutions. In particular, we market secondary aluminum coming from recycling.

We reform the main players present on the European market, which operate in various industrial sectors: food, dairy, liquids, pharmaceuticals, etc.

Thanks to the synergy and relationship of trust established with our Customers, we are able to satisfy their every need, guaranteeing high quality standards.

ALUMINUM FROM 6 TO 100 MY in alloy 8006, 8011, 8079 H0

TradeUp specializes in the marketing and processing of aluminum at the best rolling mills.

It manages mono-alloy scrap for the production of semi-finished products in the Converter range, as well as producing aluminum trays and domestic rolls. This is thanks to its subsidiaries: Gimast which deals with the environment and scrap collection and Kipack which produces the finished products.

Depending on its thickness and characteristics, aluminum can be used for various purposes:

SHEET FOR HOME USE

The sheet for domestic use, as it is sterile and highly workable/mouldable manually, is mainly used to preserve the freshness of some foods. Thanks to this feature and its resistance to high temperatures, it can also be used to wrap food during cooking.

CONTAINER SHEET

Aluminum foil is used to produce containers that are used to package human and pet food. These packages exploit some characteristics of aluminum foil, such as its formability, rigidity, excellent barrier against light and gas, good thermal conductivity and its resistance to high temperatures. These features allow you to preserve food, cook and reheat food in the microwave or traditional oven.

PACKAGING FOIL

Over the years, the physical characteristics of aluminum have made it one of the most used materials for the flexible packaging industry, guaranteeing in these uses a perfect barrier against humidity, light, odors, air and microorganisms.

Among the numerous applications of aluminum foil, the one that has been imprinted in our minds since we were children is the one used to wrap chocolate bars.

Aluminum packaging sheets find application in converters, packaging with a structure composed of multiple materials: cellulose, plastic, an aluminum film, obtained by coupling, coextrusion or lamination.

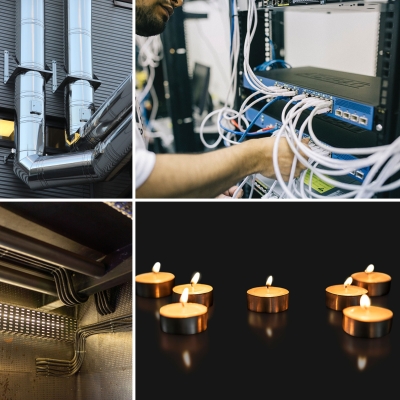

TECNICAL SHEET

The Technical Sheet is used in the industrial sector for the production of pipes and air ducts, adhesive tapes, shielding of electrical or data cables, containers for candles, for firewalls, films for rechargeable batteries, etc.

Thanks to its function as a soundproof barrier, insulation from magnetic and radio frequencies, resistance to heat, high temperatures, corrosion, waterproofness and the reflectivity of its surface, technical aluminum foil is used for various applications.

Its isotropic characteristic represents a huge advantage, as it allows the creation of deep drawings (e.g. containers for tealights).

A particular mention should be made for the use of aluminum technical sheets in Firewalls. The resistance to high temperatures and the waterproofness of aluminum make it an effective barrie.

SHEET FOR HEAT EXCHANGERS/FINSTOCK

Its lightness, good thermal and electrical conductivity and resistance to corrosion make aluminum foil the ideal material for the construction of industrial heat exchangers, which are mainly used to transfer heat from one system to another.

An example of application can be found in Heating, Ventilation and Air Conditioning systems or in refrigerators.

CIRCULAR ECONOMY

Circular economy is a model of production and consumption based on sustainability, which involves sharing, borrowing, reusing, repairing, reconditioning and recycling existing materials and products. This extends the life cycle of the products. Waste is reduced, contributing to the fight against climate change and environmental pollution.

Consumers who are increasingly attentive to the changes taking place regarding environmental responsibility prefer to direct their purchases towards companies that are committed to creating sustainable products and packaging. The consumer, with this way of acting, becomes the pivot on which to leverage to effectively promote the paradigms of the circular economy.

CIRCULAR ECONOMY

Circular economy is a model of production and consumption based on sustainability, which involves sharing, borrowing, reusing, repairing, reconditioning and recycling existing materials and products. This extends the life cycle of the products. Waste is reduced, contributing to the fight against climate change and environmental pollution.

Consumers who are increasingly attentive to the changes taking place regarding environmental responsibility prefer to direct their purchases towards companies that are committed to creating sustainable products and packaging. The consumer, with this way of acting, becomes the pivot on which to leverage to effectively promote the paradigms of the circular economy.

THE ROLE OF ALUMINUM IN THE CIRCULAR ECONOMY

During the recycling process, aluminum does not lose its distinctive properties, such as lightness, conductivity, ductility, mouldability, corrosion resistance, reflectance and amagnetism which remain unchanged. Precisely for these peculiarities, aluminum is considered the circular material par excellence.

According to what was reported by the “National Aluminum Packaging Consortium”, today Italian aluminum production is based 100% on its recycling. This practice allows you to reduce the economic costs linked to its production and have a lower environmental impact.

In fact, the production of recycled aluminum allows you to save 95% of the energy needed to produce primary aluminium.

In Italy, the recycling of aluminum packaging placed on the market is close to 78% and has already well exceeded the 2030 objectives (60%).

THE ROLE OF ALUMINUM IN THE CIRCULAR ECONOMY

During the recycling process, aluminum does not lose its distinctive properties, such as lightness, conductivity, ductility, mouldability, corrosion resistance, reflectance and amagnetism which remain unchanged. Precisely for these peculiarities, aluminum is considered the circular material par excellence.

According to what was reported by the “National Aluminum Packaging Consortium”, today Italian aluminum production is based 100% on its recycling. This practice allows you to reduce the economic costs linked to its production and have a lower environmental impact.

In fact, the production of recycled aluminum allows you to save 95% of the energy needed to produce primary aluminium.

In Italy, the recycling of aluminum packaging placed on the market is close to 78% and has already well exceeded the 2030 objectives (60%).

ADVANTAGES FOR OUR CUSTOMERS

- We provide a specific declaration that the aluminum has been recycled.

- We guarantee maximum flexibility, as we have contacts with more than 10 rolling mills and foundries all over the world.

- We guarantee transparency and certain costs with indication of the transformation + premium, added by the LME (London Metal Exchange) based on the previous month.

- We offer a scrap recovery service at customers.

ADVANTAGES FOR OUR CUSTOMERS

- We provide a specific declaration that the aluminum has been recycled.

- We guarantee maximum flexibility, as we have contacts with more than 10 rolling mills and foundries all over the world.

- We guarantee transparency and certain costs with indication of the transformation + premium, added by the LME (London Metal Exchange) based on the previous month.

- We offer a scrap recovery service at customers.